- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Container House Refrigerated/Reefer Container Offshore Container Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Other Machinery Cutting Machine Processing Machine Bending Machine Block Machine Motor Spare Parts

- Mechanical Products Vehicle Industry Miscellany Mooring Equipment Marine Equipment Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Electrical Cable Automation Power Distribution Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Fiberglass Reinforced Plastic Plastic Pipes and Pipe Fittings Pontoon System

Copper Aluminum Eutectic Row

Original material: Aluminum and copper

Grade: AL-1006 and Co-T2

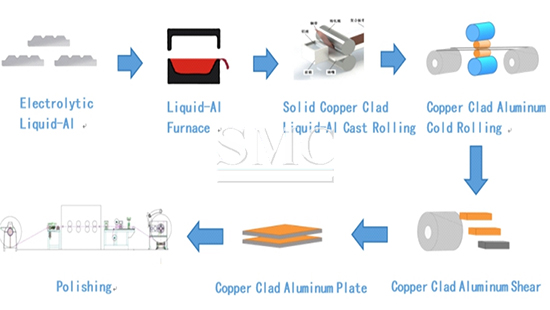

Production method: Solid-liquid casting and rolling composite

Type: Single side or double side

Shanghai Metal Corporation is a professional research and development and manufacturing of Copper aluminum eutectic row.

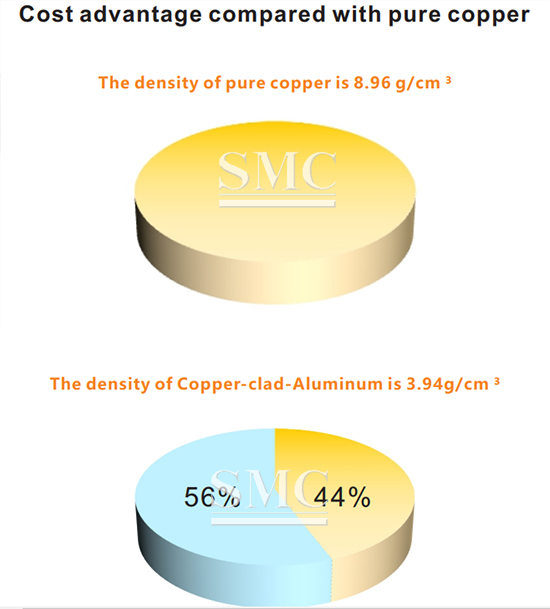

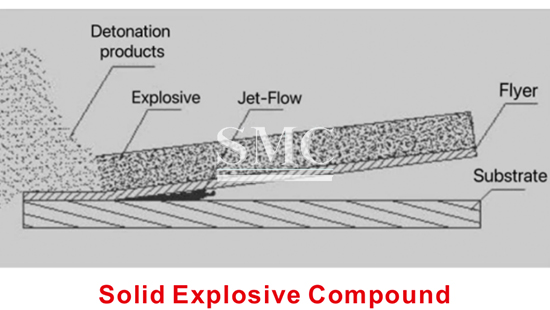

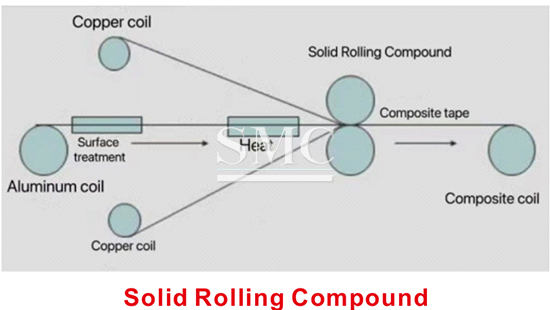

There are generally two traditional composite methods: Rolling composite method,Explosive composite method. Advantages of our company's copper-aluminum eutectic row process: We use a unique casting-rolling composite forming technology. To simultaneously introduce the solid copper plate into the copper strip during the conversion process of the aluminum liquid from liquid phase to solid phase. Through the high-temperature and high-pressure rolling of the casting roller, the atoms at the interface of the two metals jointly penetrate into the bond. The product is then cold rolled and annealed to form a unique copper-aluminum eutectic material.

If you want to know more about Copper aluminum eutectic row price please feel free to contact us, we will reply you within 24 hours

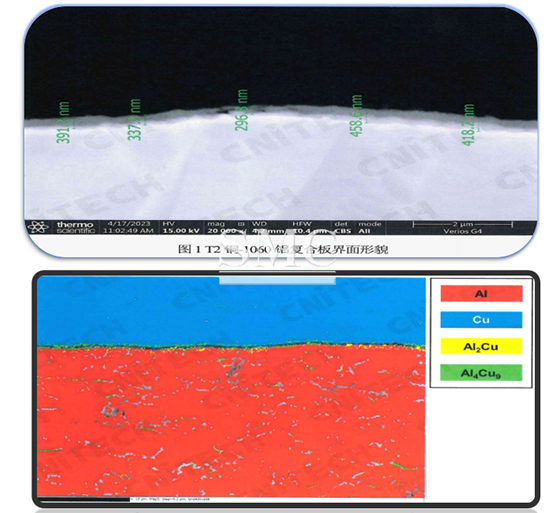

Our average thickness of Copper-clad-Aluminum interface layer is 380nm, the eutectic layer materials are Al2Cu and Al4Cu9. It realizes the metallurgical bonding between copper and aluminum, and also ensure the bonding strength between copper and aluminum. The issue of high resistivity in the transition layer is solved and there’s no burr, opening or stripping during the process of bending, drilling and punching.

The issue of high resistivity in the transition layer is solved and there’s no burr, opening or stripping during the process of bending, drilling and punching.

Specification Parameters:

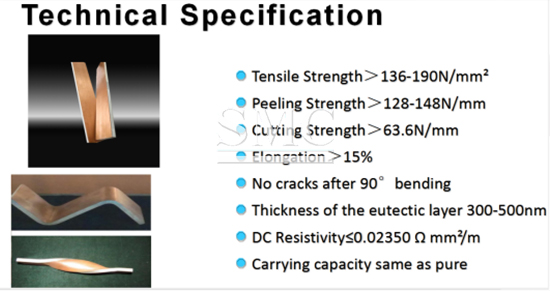

Tensile Strength>136-190MPa

Peeling Strength>128-148MPa

Shear Strength>63.6MPa

Elongation>15%

No cracks after 90°bending

Thickness of the eutectic layer 300-500nm

DC Resistivity≤0.02350Ωmm²/m

Carrying capacity same as pure copper

|

Technical Benchmarking |

|||

|

|

Industry standards/National standards |

SMC standard |

|

|

Product name |

Copper aluminum composite row (copper aluminum row) |

Copper Aluminum Eutectic Row |

|

|

Tensile strength |

≥110MPa |

140-190MPa |

|

|

Interface peel strength |

>12N/mm |

>148N/mm |

|

|

Shear strength |

>35N/mm |

>63.6N/mm |

|

|

20°DC resistivity |

≤0.02606Ωmm²/m |

≤0.02350Ωmm²/m |

|

|

Elongation |

≥11% |

≥15% |

|

|

Bending |

After the wide edge bending test of the copper aluminum composite busbar, the low magnification structure near the interface of the bent part of the product has no holes, and the product should not show cracks and bubbles. |

Bending angle 90 ° without cracks |

|

|

All indicators of the copper-aluminum eutectic row produced by our company are better than industry and national standards, especially the peeling strength is more than ten times higher than the national standard. |

|||

Typically packaged securely to prevent damage during transportation and storage. Common packaging materials include carbon box, wooden box, or custom packaging to accommodate the specific dimensions and quantity ordered.

here

for

price