- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Container House Refrigerated/Reefer Container Offshore Container Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Other Machinery Cutting Machine Processing Machine Bending Machine Block Machine Motor Spare Parts

- Mechanical Products Vehicle Industry Miscellany Mooring Equipment Marine Equipment Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Electrical Cable Automation Power Distribution Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Fiberglass Reinforced Plastic Plastic Pipes and Pipe Fittings Pontoon System

Hastelloy S

Model Number: Hastelloy S

Shape: Forging & Cold Drawn

Standard: ASTM ASME

Shanghai Metal Corporation is a professional manufacturer and supplier of Hastelloy S products with high quality and reasonable price.

If you want to know more about price of Hastelloy S products, please feel free to contact us, we will reply you within 24 hours.

-

-

Hastelloy B has excellent resistance to reducing environments like sulfuric acid at moderate concentrations and other nonoxidizing acids. It also resists stress corrosion cracking induced by chlorides. Hastelloy B has poor resistance to oxidizing environments, therefore, it should not be used where ferric or cupric salts are present as these salts may cause rapid corrosion failure.

1. Processing method:

Raw material→ Smelting→ Drawing→ Rolling→ Annealing→ Finished product→ Detection→ Packing→ Shipping

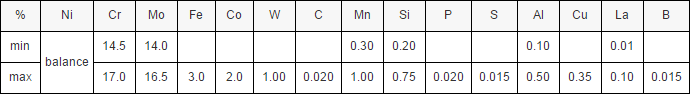

2. Chemical element for automotive fuse:

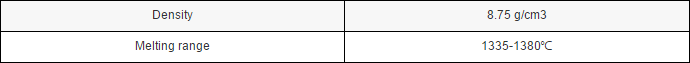

3. Physical properties:

Shanghai Metal Products are packed and labeled according to the regulations and customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation. In addition, clear labels are tagged on the outside of the packages for easy identification of the product I. D. and quality information.

1)Shanghai Metal Standard

2)Customization

HASTELLOY S was developed for applications involving severely cyclical heating conditions where components must be capable of retaining their strength, ductility, and metallurgical integrity after long-time exposure. It is used extensively as seal rings in gas turbine engines where its low thermal expansion coefficients is also important.

All wrought forms of HASTELLOY S are supplied in the solution heat treated condition unless otherwise specified. The standard heat-treatment is 1950°F (1066°C) followed by cooling in air or hydrogen. Since the alloy is very stable, cooling rates from slow-fumace cooling to rapid ice-brine quenching have virtually no effect on the mechanical properties.

HASTELLOY S alloy can be readily forged and, because of its excellent ductility, can be cold worked. It can be welded by both manual and automatic welding methods including gas tungsten arc (GTAW), and gas metal arc (GMAW). Forging should be performed from 2100°F (1145°C) to 1600°F (871°C) up to the final 20 percent cross-section reduction. The final 20 percent reduction should be done from about 1900°F (1038°C) to 1500°F (816°C).

here

for

price