- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Container House Refrigerated/Reefer Container Offshore Container Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Other Machinery Cutting Machine Processing Machine Bending Machine Block Machine Motor Spare Parts

- Mechanical Products Vehicle Industry Miscellany Mooring Equipment Marine Equipment Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Electrical Cable Automation Power Distribution Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Fiberglass Reinforced Plastic Plastic Pipes and Pipe Fittings Pontoon System

Heat Exchange Tube

Size range of finned tube: OD of base pipe:φ10mm - 88mm

Height of fin: 5mm - 16mm

Thickness of fin: 0.3mm - 0.8mm

Heat exchange tube is a main heat exchange element of heat exchange equipment, which heat exchange efficiency directly determines the performance of the whole heat exchange equipment. Besides bare tube, heat exchange equipment can also adopt heat transfer tubes made of various materials such as low finned tube, high finned tube, inner rib finned tube, threaded tube, corrugated tube, spiral tube, net work tube, T-tube, convergent-divergent tube, precision spiral tube, etc. In material, heat exchange tube can also be divided into mono-metal and bimetal which can be wildly use in the preheating and recovery of electric power, metallurgy, cement industry as well as petrochemical industry.

Technical Information of Heat Exchange Tube

Specification range:

1) Size range of finned tube: OD of base pipe:φ10mm - 88mm

2) Height of fin: 5mm - 16mm

3) Thickness of fin: 0.3mm - 0.8mm

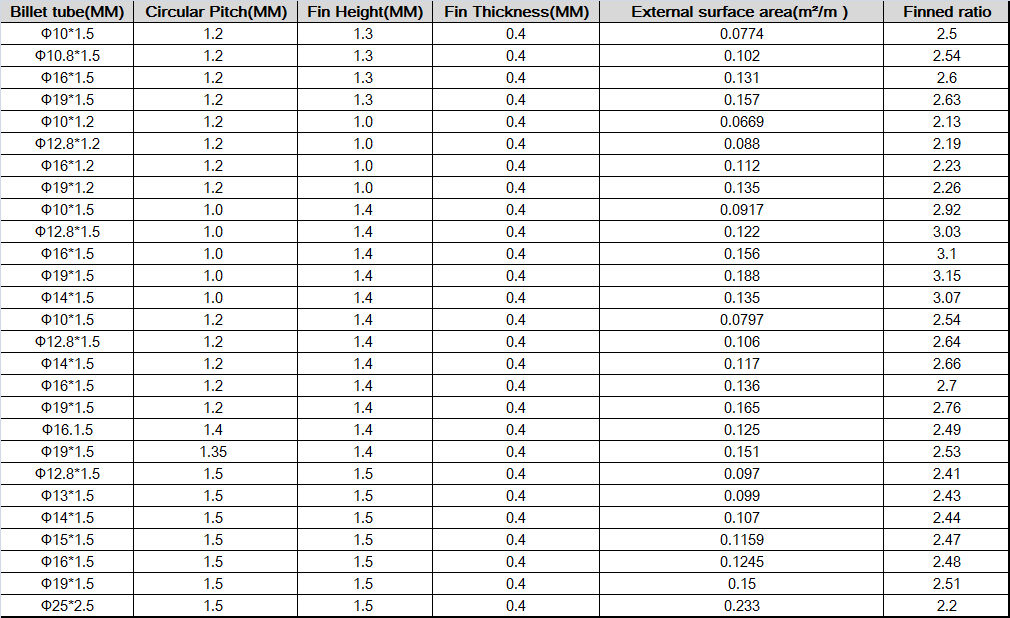

Specification table of Mono-metal high efficiency threaded heat exchange tube:

Note:

1) Parameters can be adjusted according to the demander’s drawing requirements to design and manufacture mono-metal threaded heat exchange tubes made of aluminum, copper, steel, stainless steel, or titanium tube, etc. In special specs.

2) N indicates the ratio of external surface area of threaded threaded heat exchange tube before rolling.

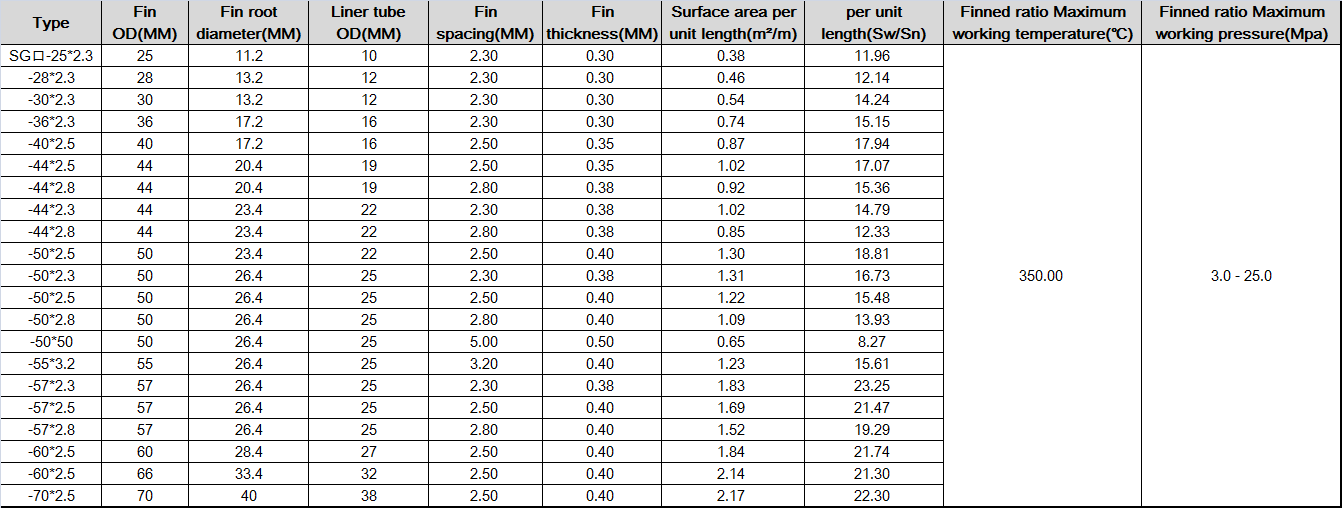

Type and Spec. of Bimetal rolled integral fin tube:

Noted:

1) □ indicates a symbol of liner tube material,e.g. red copper is “T” steel and “G” grade. The user can freely choose copper tube, steel tube or titanium tube, etc. as liner tube according to the requirements of medium used in heat exchange tube.

2) Sn rolled integral fine tube indicates the surface area calculated based on I.D. of aluminum tube (O.D. of liner tube)

3) Besides the Spec. shown on the table, we can also design and manufacture bimetal rolled integral fin tubes in any special Specs.

Packaging of Heat Exchange Tube

Shanghai Metal Products are packed and labeled according to the regulations and customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation. In addition, clear labels are tagged on the outside of the packages for easy identification of the product I. D. and quality information.

1) Shanghai Metal Standard

2) Customization

Applications of Heat Exchange Tube:

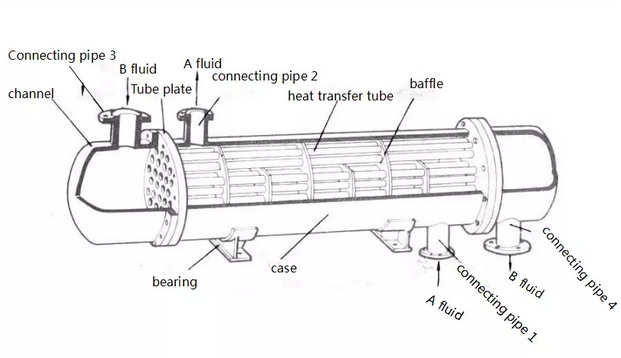

Tube shell type heat exchange

Shell and tube heat exchanger is one of the most typical partition type heat exchangers. It has a long history of application in industry and lays a dominant position among all heat exchanger until now. Heat exchange tube is the main element of it.

Advantages of Heat Exchange Tube:

1) High heat transfer

2) Wide scope of application

3) Applicable to various complications

4) Compact in structure, small in size

5) Convenient for maintenance and repaire

Features of SMC Heat exchange tube:

1) Anticorrosion property

2) Wear resistance property

3) Low thermal contact resistance

4) Extremely high tability

5) Super anti-fouling capability

here

for

price