- Company overview The heart of SMC Vision & Philsophy Partnership Certifications Company culture

- Our service Design and Engineering Maintenance and Service Examine Production Line Upgrade and Transformation Storage and Logistics Processing, Trading and Distributor

- Management Our history Global responsibility Info Center

- Procurement center Internship

- Metal Steel Products Stainless Steel Products Aluminum Products Copper Products Galvanized Steel and PPGI Special Alloy Building Material

- Containers ISO Standard Container Equipment Container Storage Container Container House Refrigerated/Reefer Container Offshore Container Tank Container Container Fittings Container Trailer

- Gas Cylinder & Fire Extinguisher Cryogenic Liquid Cylinder Oxygen Gas Cylinder Storage Tank CNG Gas Cylinder LPG Gas Cylinder Hydrogen Gas Cylinder Nitrogen Gas Cylinder Industry Gas Cylinder Fire Extinguisher

- Metal Machinery Forming Machine Other Machinery Cutting Machine Processing Machine Bending Machine Block Machine Motor Spare Parts

- Mechanical Products Vehicle Industry Miscellany Mooring Equipment Marine Equipment Pressure Vessel Conveyor Belt Laser Equipment Bearing

- Electrical System Electrical Cable Automation Power Distribution Solar Power System Electric Protection System Transformer Production Line Lighting System

- Project Fiberglass Reinforced Plastic Plastic Pipes and Pipe Fittings Pontoon System

Hot Dip Galvanized Steel Coil

Thickness: 0.12mm-6.0mm

Width: 600mm-1500mm, or as per client’s request

Zinc Coating: Z40-Z600

Hot-dip galvanized steel coil is suitable for fabrication by forming, pressing and bending because of its excellent forming property, painting ability, welding ability. It is mainly used in construction, home appliances, automobiles, machinery, electronics, light industry and other industries. Shanghai metal Corporation is a professional manufacturer and supplier of Hot-dip galvanized steel coil with high quality and reasonable price.

If you want to know more about Hot-dip galvanized steel coil products or Hot-dip galvanized steel coil price please feel free to contact us, we will reply you within 24 hours.

1. Standard, steel grade & application:

|

Type |

Steel Quality |

Steel Grade |

Standard |

Equivelent Steel Grade |

Application |

|

low carbon steel and super low carbon steel |

commercial quality CQ |

DX51D+Z |

GB/T 2518-2008 |

SGCC |

general forming metal products |

|

DX51D+ZF |

|||||

|

drawing quality DQ |

DX52D+Z |

SGCD1 |

drawing metal products |

||

|

DX52D+ZF |

JAC270C |

||||

|

deep drawing quality DDQ |

DX53D+Z |

SGCD2 |

deep drawing metal products |

||

|

DX53D+ZF |

JAC270D |

||||

|

extra-deep drawing quality EDDQ |

DX54D+Z |

SGCD3 |

extra-deep drawing products |

||

|

DX54D+ZF |

JAC270E |

||||

|

carbon structural steel and low alloy steel |

commercial quality high speed steel CQHSS |

S220GD+Z |

|

structural steel |

|

|

S250GD+Z |

SGC340 |

||||

|

S280GD+Z |

SGC400 |

||||

|

S320GD+Z |

SGC440 |

||||

|

S350GD+Z |

SGC590 |

||||

|

S550GD+Z |

|

2. Mechnical property:

|

Steel Grade |

Yield strength MPA |

Tensile strength MPA |

Elongation A80mm% min |

180° Bending Test d=a |

|

DX51D+Z |

/ |

270-550 |

22 |

no drop |

|

DX52D+Z |

140-300 |

270-420 |

26 |

no drop |

|

DX53D+Z |

140-260 |

270-380 |

30 |

no drop |

|

DX54D+Z |

120-220 |

270-350 |

36 |

no drop |

3. Coating mass:

|

Zinc structure |

Zinc Sympol |

Min value for two sides g/m2 |

Density g/m2 |

|

|

at three ponit |

at one point |

7.1 |

||

|

pure zinc(z) |

Z100 |

100 |

85 |

|

|

Z140 |

140 |

120 |

||

|

Z200 |

200 |

170 |

||

|

Z225 |

225 |

195 |

||

|

Z275 |

275 |

235 |

||

|

Z450 |

450 |

385 |

||

|

Z600 |

600 |

510 |

||

4. Width tolerance:

|

Nominal width mm |

Allowed tolerance(mm) |

|||

|

PW.A |

PW.B |

|||

|

Min |

Max |

Min |

Max |

|

|

≥600-1200 |

0 |

5 |

0 |

2 |

|

>1200-1500 |

0 |

6 |

0 |

2 |

5. Flatness:

|

Nominal width mm |

Flateness not more than /mm |

|||||

|

PF.A |

PF.B |

|||||

|

Nominal thickness mm |

||||||

|

﹤0.7 |

≥0.7~1.2 |

≥1.2 |

﹤0.7 |

≥0.7~1.2 |

≥1.2 |

|

|

≥600~1200 |

12 |

10 |

8 |

5 |

4 |

3 |

|

≥1200~1500 |

15 |

12 |

10 |

6 |

5 |

4 |

|

≥1500 |

19 |

17 |

15 |

8 |

7 |

6 |

Packaging of Hot Dip Galvanized Steel Coil

Shanghai Metal Products are packed and labeled according to the regulations and customer's requests. Great care is taken to avoid any damage which might be caused during storage or transportation. In addition, clear labels are tagged on the outside of the packages for easy identification of the product I. D. and quality information.

1) Shanghai Metal Standard

2) Customization

Applications of Hot Dip Galvanized Steel Coil:

1) Construction and building: roofing, ventilating duct, handrail, partition panel, etc.

2) Further processing: coating base plate

3) Electric appliance: refrigerator, washing machine, recorder, microwave, etc.

What is Galvanized Steel?

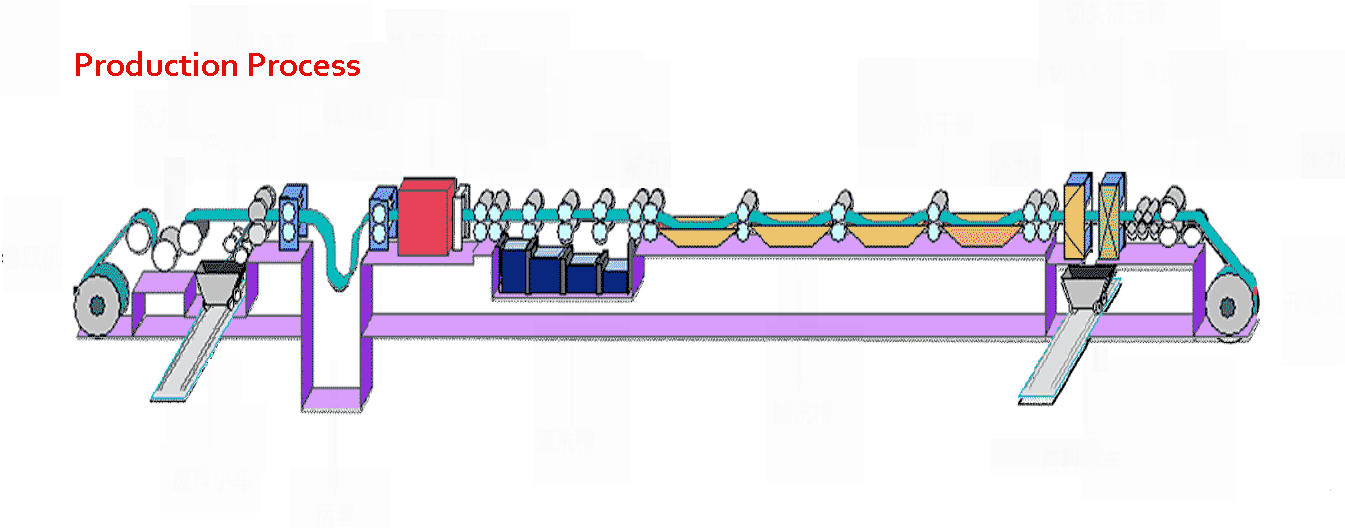

There are two typical galvanizing ways to obtain a zinc coating: hot dip galvanizing and electrogalvanizing. Hot dip galvanizing is the process that steel is immersed into molten zinc bath to get a zinc coating surface. This not only helps protect steel from rust and corrosion, but also gives the steel a shiny attractive appearance. Electrogalvanizing is the process that uses electrolysis to coat the steel with zinc, which is neither cost-effective nor environmentally friendly. It is hardly to find electrogalvanized steel in our lives nowadays.

What are the advantages of Galvanized Steel?

Because of permanently and successive zinc/iron alloy layers, galvanized steel offers many benefits:

1) Corrosion Resistance: the zinc coating surface protects the base steel not only by providing barrier to corrosion elements, but also by the sacrificial nature of the coating. Galvanized steel often remains in working order with little maintenance for 40 years or more.

2) Excellent Surface Appearance

3) Formability: it can be simply bend to parts with deep drawing requirements

4) Paintability: it can be painted with different colors

5) Weldability: it is accepted various welding practices

What are the disadvantages of Galvanized Steel?

In spite of many benefits, galvanized steel is not always an ideal choice. Galvanized steel cannot be used underground without being properly covered, which can be inconvenient for many jobs.

Where do we use Galvanized Steel?

It is primarily used in the construction industry, such as roofing, wall cladding, and support beams. It is also used in the automotive industry, due to its enhanced paintability, weldability and corrosion resistance. Moreover, it is an essential material for white goods application, such as refrigerators, air-conditioners, washers, microwaves, vending machines and audio visual systems.

here

for

price